| Availability: | |

|---|---|

| Quantity: | |

1.Main Technical Parameters

A. Model | 1300 | 1500 | 1700 |

B. Material Width(mm) | 1270 | 1470 | 1670 |

C. Unwinding diameter(mm) | 600 | 600 | 600 |

D. Rewinding diameter(mm) | 450 | 450 | 450 |

E. Inner diameter of unwinding&rewinding(mm) | 52&76 (2&3 inch) | 52&76 (2&3 inch) | 52&76 (2&3 inch) |

F. Slitting precision(mm) | <0.5 | <0.5 | <0.5 |

G. Minimum slitting width(mm) | 20 | 20 | 20 |

H. Speed(m/min) | 10-200 | 10-200 | 10-200 |

I. Slitting blades | Straight/ circular | Straight/ circular | Straight/ circular |

J. Total power(kw) | 5 | 7 | 7 |

K. size(M) | 1.8*1.7*1.6 | 1.8*1.9*1.6 | 1.8*2.1*1.6 |

L. Weight(kg) | 2300 | 2500 | 2800 |

2.Comprehensive Description

3. Product Features

(1) The unwinding unit is automatically loaded with a pneumatic cylinder and does not require additional auxiliary machinery to reduce the labor intensity of workers

(2) The automatic web guide system comes with photoelectric sensor and is executed by a precision screw motor. Closed-loop control design enables high-precision edge control

(3) The main motor is driven by double chains and the winding unit uses magnetic powder for clutch control

(4) The winding shaft adopts a bearing set as a coupling device to reduce the resistance and improve the transmission accuracy

(5) The rewinding unit uses slip pneumatic shafts for balance compensation. Specially designed for a variety of uneven thickness, elastic special substrate, to ensure tight rolling, smooth edges.

1.Main Technical Parameters

A. Model | 1300 | 1500 | 1700 |

B. Material Width(mm) | 1270 | 1470 | 1670 |

C. Unwinding diameter(mm) | 600 | 600 | 600 |

D. Rewinding diameter(mm) | 450 | 450 | 450 |

E. Inner diameter of unwinding&rewinding(mm) | 52&76 (2&3 inch) | 52&76 (2&3 inch) | 52&76 (2&3 inch) |

F. Slitting precision(mm) | <0.5 | <0.5 | <0.5 |

G. Minimum slitting width(mm) | 20 | 20 | 20 |

H. Speed(m/min) | 10-200 | 10-200 | 10-200 |

I. Slitting blades | Straight/ circular | Straight/ circular | Straight/ circular |

J. Total power(kw) | 5 | 7 | 7 |

K. size(M) | 1.8*1.7*1.6 | 1.8*1.9*1.6 | 1.8*2.1*1.6 |

L. Weight(kg) | 2300 | 2500 | 2800 |

2.Comprehensive Description

3. Product Features

(1) The unwinding unit is automatically loaded with a pneumatic cylinder and does not require additional auxiliary machinery to reduce the labor intensity of workers

(2) The automatic web guide system comes with photoelectric sensor and is executed by a precision screw motor. Closed-loop control design enables high-precision edge control

(3) The main motor is driven by double chains and the winding unit uses magnetic powder for clutch control

(4) The winding shaft adopts a bearing set as a coupling device to reduce the resistance and improve the transmission accuracy

(5) The rewinding unit uses slip pneumatic shafts for balance compensation. Specially designed for a variety of uneven thickness, elastic special substrate, to ensure tight rolling, smooth edges.

C. The main motor is driven by double chains and the winding unit uses magnetic powder for clutch control:

D. The rewinding shaft adopts a bearing set as a coupling device to reduce the resistance and improve the transmission accuracy:

F. In constant tension mode, each slip ring can be automatically fine-tuned so that each finished roll remains tight:

C. The main motor is driven by double chains and the winding unit uses magnetic powder for clutch control:

D. The rewinding shaft adopts a bearing set as a coupling device to reduce the resistance and improve the transmission accuracy:

F. In constant tension mode, each slip ring can be automatically fine-tuned so that each finished roll remains tight:

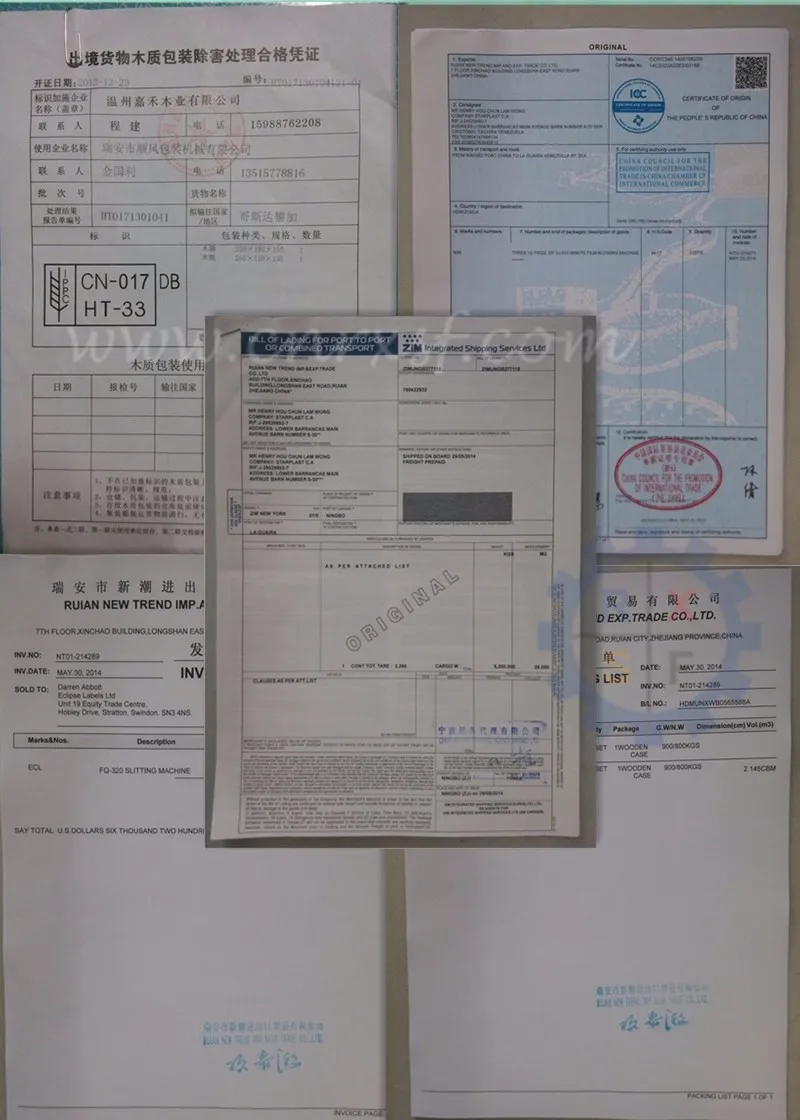

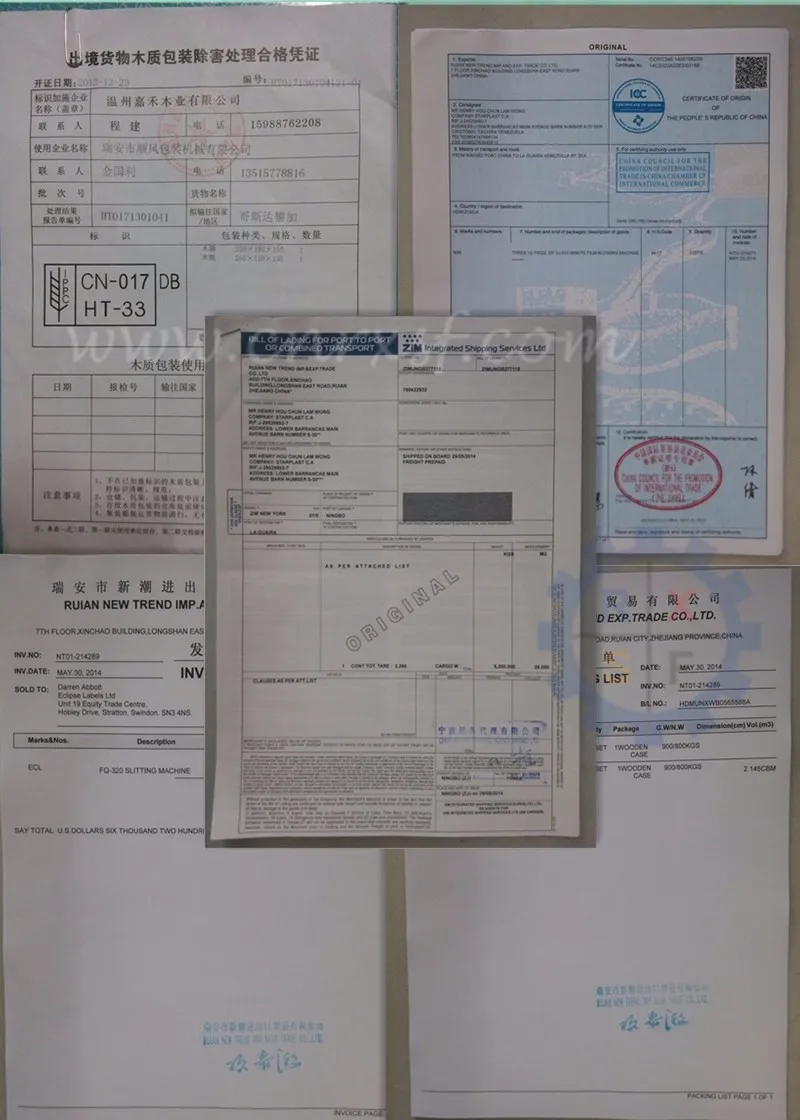

6. Trading terms and after sales service

6. Trading terms and after sales service