| Availability: | |

|---|---|

| Quantity: | |

1.Main Technical Parameters

A. Model | 1100 | 1500 | 1700 |

B. Material Width(mm) | 1070 | 1470 | 1670 |

C. Unwinding diameter(mm) | 600 | 600 | 600 |

D. Rewinding diameter(mm) | 450 | 450 | 450 |

E. Inner diameter of unwinding&rewinding(mm) | 52&76 (2&3 inch) | 52&76 (2&3 inch) | 52&76 (2&3 inch) |

F. Slitting precision(mm) | <0.5 | <0.5 | <0.5 |

G. Minimum slitting width(mm) | 20 | 20 | 20 |

H. Speed(m/min) | 10-200 | 10-200 | 10-200 |

I. Type of puncture roller | Copper/inner heating | Copper/inner heating | Copper/inner heating |

J. Power of puncture roller(kw) | 8 | 12 | 14 |

K. Slitting blades | Straight/ circular | Straight/ circular | Straight/ circular |

L. Total power(kw) | 12 | 18 | 20 |

M. size(M) | 1.8*1.5*1.6 | 1.8*1.9*1.6 | 1.8*2.1*1.6 |

N. Weight(kg) | 2100 | 2500 | 2800 |

2.Comprehensive Description

3. Product Features

(1) The unwinding unit is automatically loaded with a pneumatic cylinder and does not require additional auxiliary machinery to reduce the labor intensity of workers

(2) The automatic web guide system comes with photoelectric sensor and is executed by a precision screw motor. Closed-loop control design enables high-precision edge control

1.Main Technical Parameters

A. Model | 1100 | 1500 | 1700 |

B. Material Width(mm) | 1070 | 1470 | 1670 |

C. Unwinding diameter(mm) | 600 | 600 | 600 |

D. Rewinding diameter(mm) | 450 | 450 | 450 |

E. Inner diameter of unwinding&rewinding(mm) | 52&76 (2&3 inch) | 52&76 (2&3 inch) | 52&76 (2&3 inch) |

F. Slitting precision(mm) | <0.5 | <0.5 | <0.5 |

G. Minimum slitting width(mm) | 20 | 20 | 20 |

H. Speed(m/min) | 10-200 | 10-200 | 10-200 |

I. Type of puncture roller | Copper/inner heating | Copper/inner heating | Copper/inner heating |

J. Power of puncture roller(kw) | 8 | 12 | 14 |

K. Slitting blades | Straight/ circular | Straight/ circular | Straight/ circular |

L. Total power(kw) | 12 | 18 | 20 |

M. size(M) | 1.8*1.5*1.6 | 1.8*1.9*1.6 | 1.8*2.1*1.6 |

N. Weight(kg) | 2100 | 2500 | 2800 |

2.Comprehensive Description

3. Product Features

(1) The unwinding unit is automatically loaded with a pneumatic cylinder and does not require additional auxiliary machinery to reduce the labor intensity of workers

(2) The automatic web guide system comes with photoelectric sensor and is executed by a precision screw motor. Closed-loop control design enables high-precision edge control

C. Inner heated copper ring piercing roller, with temperature resistant silicone roller, puncture the hole while achieving thermal shrinkage, to produce breathable films with excellent waterproof and breathable properties:

D. Double toolholder for loading flat blades & round blades. In addition to breathable film, it can also be used for slitting and rewindingsuitable for a variety of flexible packaging materials:

F. Magnetic powder-air shaft winding design, the edge of the film roll is smooth like a mirror:

G. Breathable membranes are widely used in the packaging of foods and medicines to achieve a "breathable but moisture-proof" function:

H. Puncture effect under the 100 times magnifying glass - to ensure breathability, waterproof. The edge of the hole is heat shrinked and will not easily tear:

C. Inner heated copper ring piercing roller, with temperature resistant silicone roller, puncture the hole while achieving thermal shrinkage, to produce breathable films with excellent waterproof and breathable properties:

D. Double toolholder for loading flat blades & round blades. In addition to breathable film, it can also be used for slitting and rewindingsuitable for a variety of flexible packaging materials:

F. Magnetic powder-air shaft winding design, the edge of the film roll is smooth like a mirror:

G. Breathable membranes are widely used in the packaging of foods and medicines to achieve a "breathable but moisture-proof" function:

H. Puncture effect under the 100 times magnifying glass - to ensure breathability, waterproof. The edge of the hole is heat shrinked and will not easily tear:

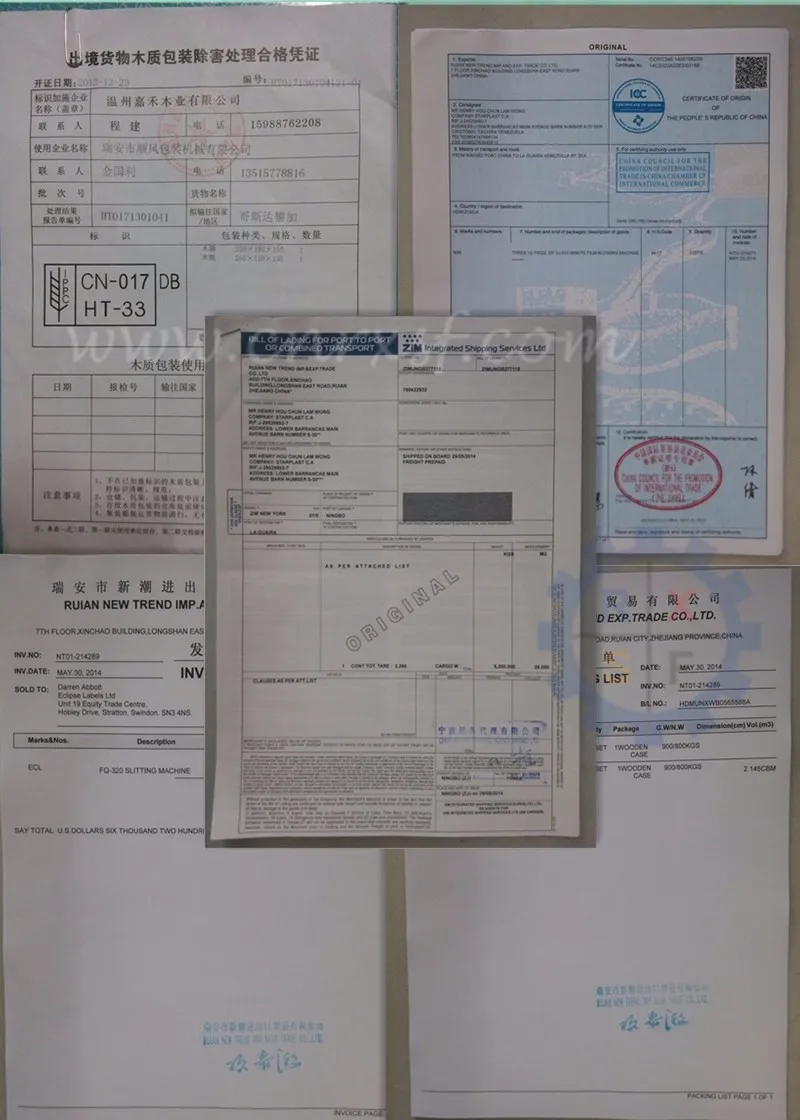

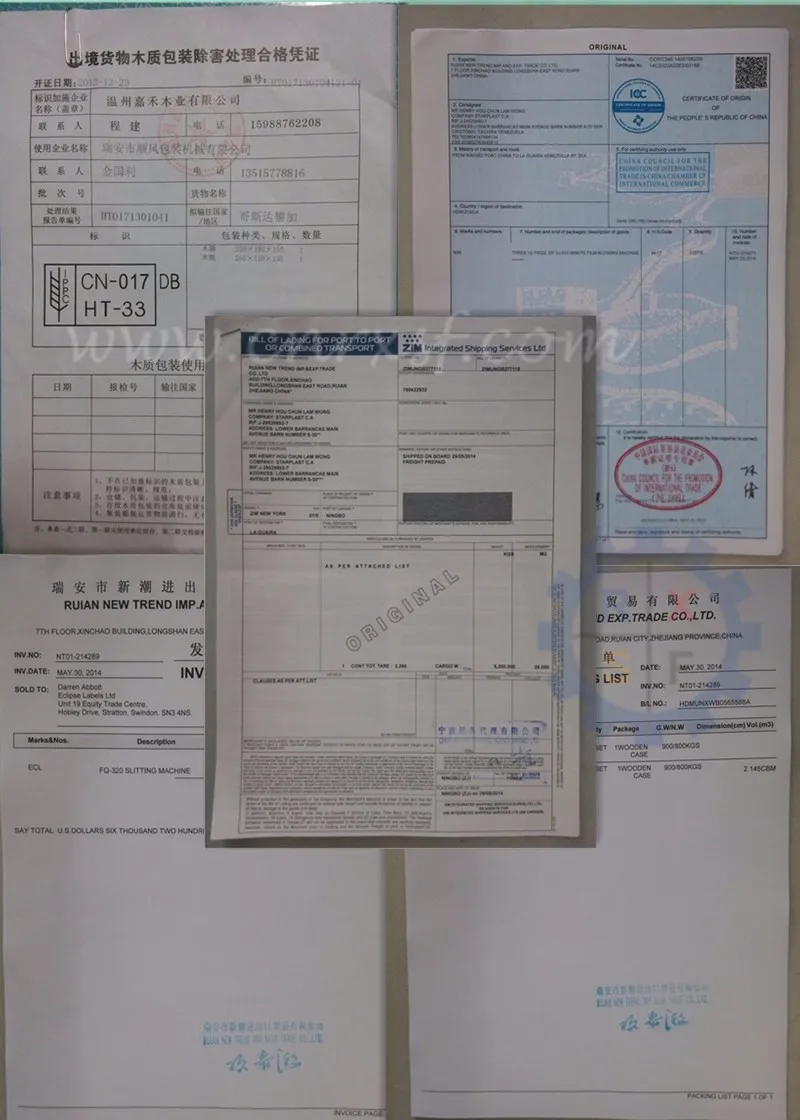

6. Trading terms and after sales service

6. Trading terms and after sales service